Portland's Handyman

Stay Wild

Meet the Legendary Leatherman

Story by Cameron Vigliotta // cameronvigliotta.com

Photos by Anthony Aquino // @anthony__aquino

In time, he finished the tedious job and handed me the Leatherman, instructing me to tuck it back into its case. I felt its cold, stainless steel build pass through my weeny hands as I studied the characters on its surface. Ruler markings lined its edges. “Leatherman Tool” was engraved on the side. Hesitantly, I placed it in the kitchen junk drawer amongst an assortment of tools and clutter; it was the very same catchall junk drawer that occupies space in most every American kitchen.

Years passed on and still my father’s Leatherman somehow managed to stick around. It was always rather loyal in that way. As his birthday approached only days beyond the new year, I strategized excitedly with my mother to buy him a new one. We sifted through the company’s multitool inventory before appointing the Leatherman Blast to become his latest everyday assistant.

When the big day finally arrived, I handed him the new tool in its hallmark leather case. It was a serious upgrade over the previous model he’d used for so long, the Leatherman PST—the original Leatherman Pocket Survival Tool. I found myself excited by the notion that he’d have a new tool in his life, another everyday instrument that was sure to last a lifetime. Secretly, I found myself more excited knowing I’d inherit his old Leatherman.

And soon after, I did.

This reads like the story of so many that choose to welcome Leatherman into their lives. The narrative always manages to evoke the notion of heritage, family, and, perhaps, humble beginnings. I discovered Leatherman because someone else had one in their hands. And quickly I realized that I wanted one too, as so many of us do.

I think of that peculiarity as I sit across the room from Adam Lazenby, Leatherman’s head designer. In his hand is a gadget released only months ago as part of the company’s newfound multitool collection, the Leatherman Free series. Nine Free multitools have made the cut under his inquisitive eye. I notice the tool in his hand and again grow transfixed, just as I had so long ago.

“It starts to feel like my hand is better than it was before because it’s so effortless,” Lazenby says. “The whole thing is much more ergonomic.” In his hand, a Leatherman Free progresses through a series of clicks and snaps, each one firm and comforting as tools lock into place. The Leatherman moves with such ease and freedom that a quick glance might lead one to assume he’s fiddling with nothing more than a metallic fidget spinner. “If we can create a tool that is pleasant enough to touch that people will just naturally start playing with it, then we know we have succeeded,” he confirms.

But a single word from the, ahem, unfolding conversation seems to resonate with Lazenby more so than any other: freedom. I say that because Lazenby prides himself on freedom. At 36 years old, he lives with his family on a sailboat and bicycles to work each day, all in rather modest fashion. It’s a lifestyle he’s chosen to lead for a few years now.

Before buying the boat, he and his partner lived life in a van. They did so if only to enjoy the present moment, and the moments to come. “We wanted to save money in a way that guaranteed adventure,” he says. “We really enjoyed that easygoing, free lifestyle of ‘if you want to have fun, just go.’”

When asked how he defines freedom, Lazenby pauses. I can see the gears turning as he ponders, searching for a simple response.“Freedom is being able to go until you choose to stop,” he answers rather stoically. “Choosing when and where to have an adventure without being hampered by logistics—that we can just up and go—there’s something incredibly beautiful about that.”

Perhaps only more compelling than Lazenby’s personal life is a lineage that can be traced from his perception of freedom to that of the Leatherman Free series, a project that took five years to bring to market. While the original Leatherman was famous for its butterfly design, everything you needed was on the inside, stowed away in hiding. With the Free series, tools now face out, removing the need to open the Leatherman simply to access one. With the flick of a thumb or push of a metal release, most any tool can now be opened with one hand, even without a fingernail. “When you have a problem, you can fix it,” Lazenby said. “There’s very little holding you back. It’s just right there, ready to go.”

I walk down the hall towards a room nicknamed “the torture chamber.” Leatherman’s headquarters evoke a similar notion of freedom, simplicity, and small beginnings. Located unassumingly in Portland, Oregon, the company both designs and manufactures every Leatherman tool here from start to finish. Around the workplace, desks are covered in assortments of tools, both constructed and deconstructed. Some workbenches resemble Dr. Frankenstein’s laboratory bench over that of a modern day engineer’s. Parts from various Leatherman products are scattered in seemingly randomized fashion.

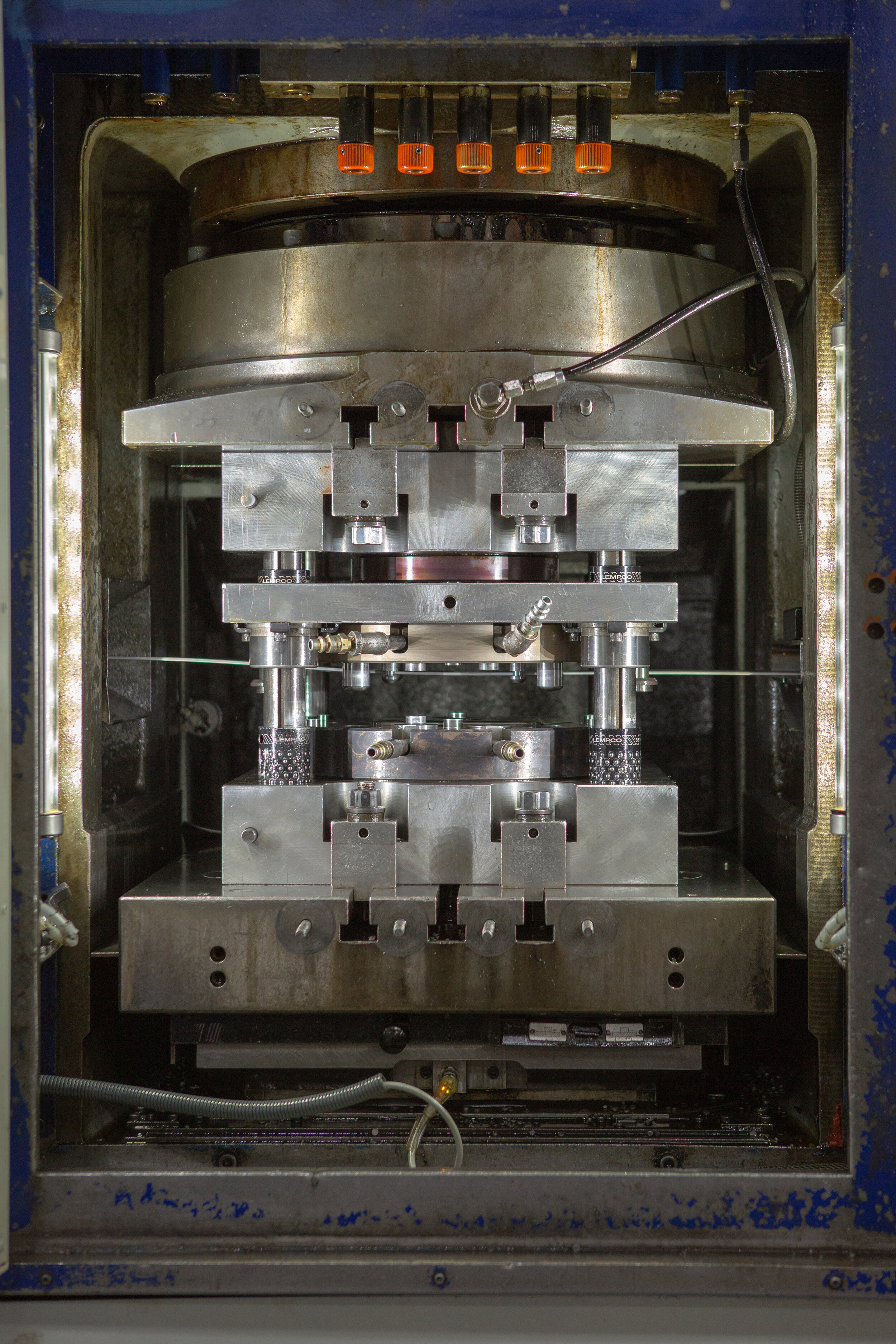

As we enter the product testing space, the rhythmic sound of pneumatic motors provides a soothing white-noise backdrop. Blades open and close thousands of times as engineers test the breaking point of every tool in every possible manner. A composite glass chamber that houses a hydraulic press is covered in scratches and nicks from Leatherman tools that are squeezed to the point of explosion. An oxidation rig exposes tools to years of moisture damage in a matter of hours or days. And buckets of defeated parts closely resemble a graveyard of tools that made the sacrifice to whatever better innovations come next.

The sophisticated equipment dispersed throughout the open room captures the transformation of the Leatherman brand. When the company’s founder, Tim Leatherman, launched the first Leatherman tool in 1983, he did so with far simpler intentions. “There were often times where a pocket knife wasn’t quite adequate, and I also needed a pair of pliers,” recalls Tim. “I was jotting down notes, and one of the notes in essence said, ‘Add pliers to a pocket knife.’” And so he did.

Tim is what one might consider the quintessence of small beginnings. An easygoing man, he evokes memories of your high school shop teacher. Wiry frames rest on his nose while he sports a collared, button-down shirt that serves equal parts presentability and function—in most instances, the top button is undone. Perhaps a pen or two emerge from his breast pocket while grey corduroy pants are held up by a belt with holsters; in one is a flashlight, and in the other his titanium Leatherman.

His original idea for a multitool design stemmed from a cross-country road trip through Europe and the Middle East that was highlighted by repair sessions on a rundown 1969 Fiat 600. After realizing his pocket knife lacked a pair of much-needed pliers, Tim returned to Portland, Oregon where he took eight years to produce the very first Leatherman tool in his garage. Despite initial hesitation from most every knife and tool catalog in the country, Tim was soon filling orders for 500, 750, and even 1,000 Leatherman PSTs per week.

Back in the “torture chamber,” Tim cuts a seatbelt with one of the Leatherman brand’s many tools. As it turns out, the device has saved countless lives from car crashes, and the company therefore needs to ensure its life-saving duties.

Tim goes on to perform his signature test as he removes a business card from his pocket. With the wire cutters from his Leatherman, Tim makes a few cuts in the edge of the paper card, illustrating the tool’s precision. But then he goes a few steps further, inserting a 12-gauge nail into the wire cutters before clamping down until the nail cuts cleanly in half. He performs this test around the world with his personal Leatherman, and does so without fail.

Beyond the testing room, Tim provides a tour of the manufacturing floor. What starts as a spool of steel from a mill in Ohio becomes the very multitool that rests on his hip. Each step of the production process is treated like a small business in which utilizing the very best materials translates to a purposeful tool for the customer. Everything is constructed with trust and pride in this space.

On a separate rack of the production floor sit the many die castings that form each and every Leatherman tool SKU. Equivalent in price to that of a car, each individual die is far more valuable than one might assume upon first glance; Tim aptly named the huge rack of dies his “parking garage.”

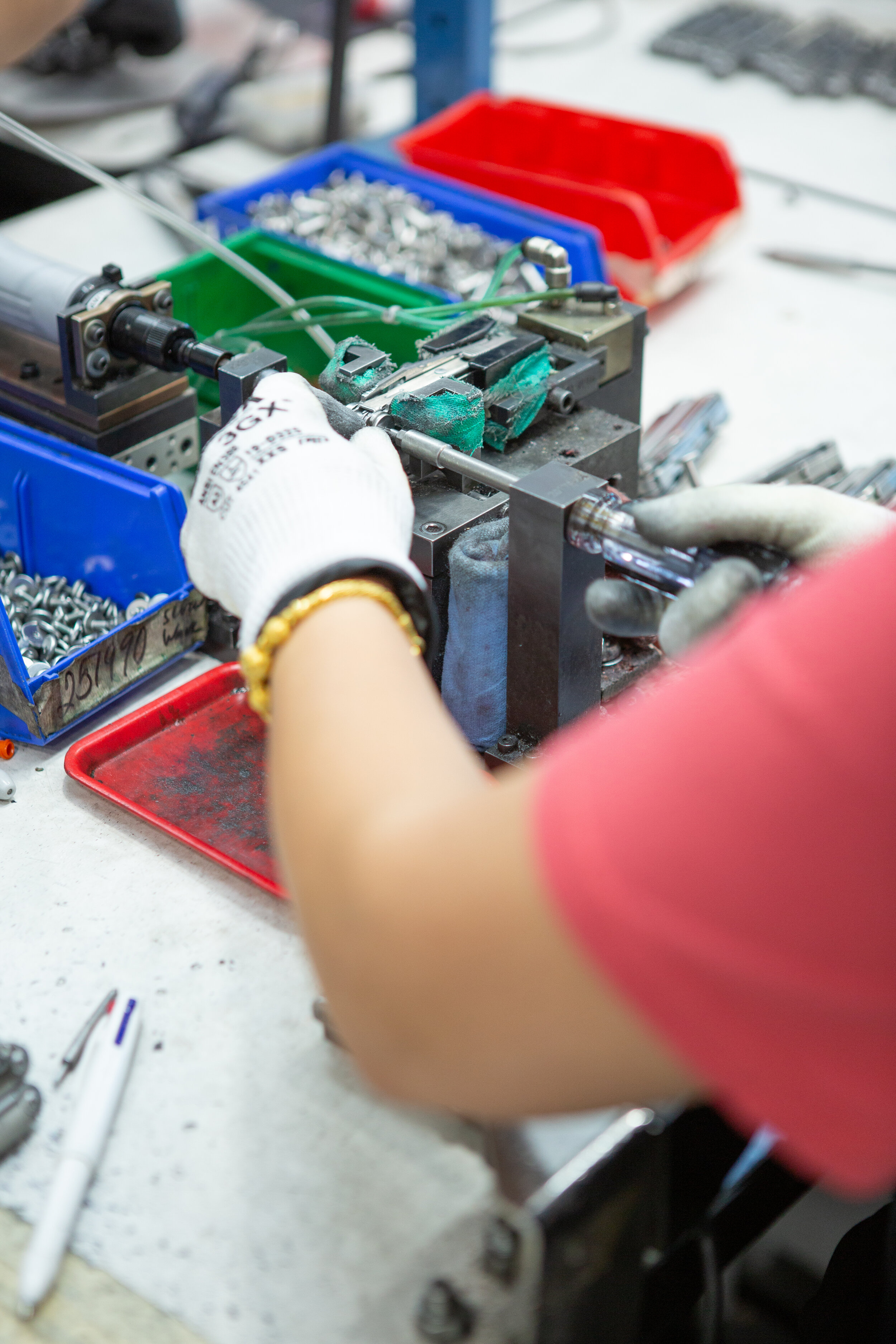

The production process on the floor feels rather human. Leatherman takes pride in employing American workers to produce their tools rather than relying entirely on automation that continues to phase out jobs. The company has instead expanded as new positions become available—a rarity in modern American manufacturing. “I’m really proud of the jobs created as a result of the success of Leatherman tool,” notes Tim. “That’s probably, to me, my greatest legacy, the jobs created here in Portland, Oregon.”

And while one might assume the factory floor would be a scene of lumbering men in flannels and Carhartts that just returned from a night’s stay in the Mt. Hood National Forest, in fact it is anything but. Instead, everyone from each walk of life is present and accounted for. Oddly enough, it all feels a bit like family.

As we prepare to leave, Tim reveals a dremel tool and signs our various Leatherman that we’d brought along for the journey—the one my father handed down to me included. Afterwards he places the dremel tool into a homemade sheath, fashioned out of an old toothpaste container. In time, we say our goodbyes.

There’s something about that single gesture that encapsulates the Leatherman brand so well.

Leatherman’s worldwide success is a product of the greatest multitooled minds that work together with a sense of humble passion. The company, no matter how much they may grow, remains small at heart in a location nestled discreetly along the Columbia River. The Leatherman is a symbol of Americana, that rare functional object passed down from father to son, and so on. It’s the tool that’s made appearances in the X Files, Speed, The Hurt Locker, and other Hollywood blockbusters. It’s also the same tool that millions of us carry and put to use every single day.

Perhaps 15 years have passed since my father’s Leatherman PST came into my possession, and still it remains close by. So close, in fact, that I could blindly unzip a small pocket on my backpack with the flick of two fingers to unveil it once again. As I upgrade my Leatherman multitool to something a little more modern, the old one passed down by my father sits on a shelf for display. Rest assured, a day will come when it’s needed once again. And when that day comes, it will always be ready, leaving nothing undone.